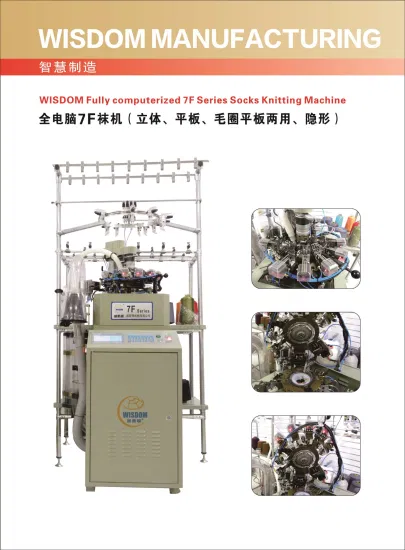

Coton Sock Kitting Machine with All Accessories and Auxiliaries Suitable for All Size of Sock. Final Product Will Be Both Terry and Plain. with Latest Technolog

Brief introduction: 1, Application This is 3.75 inch terry and plain socks making machine which is designed as a double-

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | huaruijiahe |

| Knitting Style | Flat |

| Knitting Method | Double |

| Needle Style | Latch Needle |

| Needle Bar Style | Circular Knitting Machine |

| Computerized | Computerized |

| Certification | CE, ISO9001: 2000 |

| Condition | New |

| Working Experience | 32 Years′ Experience |

| Warranty Time | Offer Free Spare Parts and Service Within 12 Month |

| Output Speed | 280~330 r.p.m |

| Needle Count | 84n~168n, 200n |

| Delivery Date | Fast Delivery in 7 Days |

| Price | Lowest Reasonable Offers in The Market |

| After-Sales Service | 24 Hours Technical Support by Email, Call, Video |

| Voltage | 380V/50Hz 3phase Can Be Customized |

| Machine Painting Color | Be Made According to Your Need |

| Machine Item | Coton Sock Kitting Machine with All Accessories |

| Transport Package | Standard Package or Nude Package Customized |

| Specification | 280~330 R. P. M |

| Trademark | HUARUI |

| Origin | Qingdao City |

| HS Code | 84451112 |

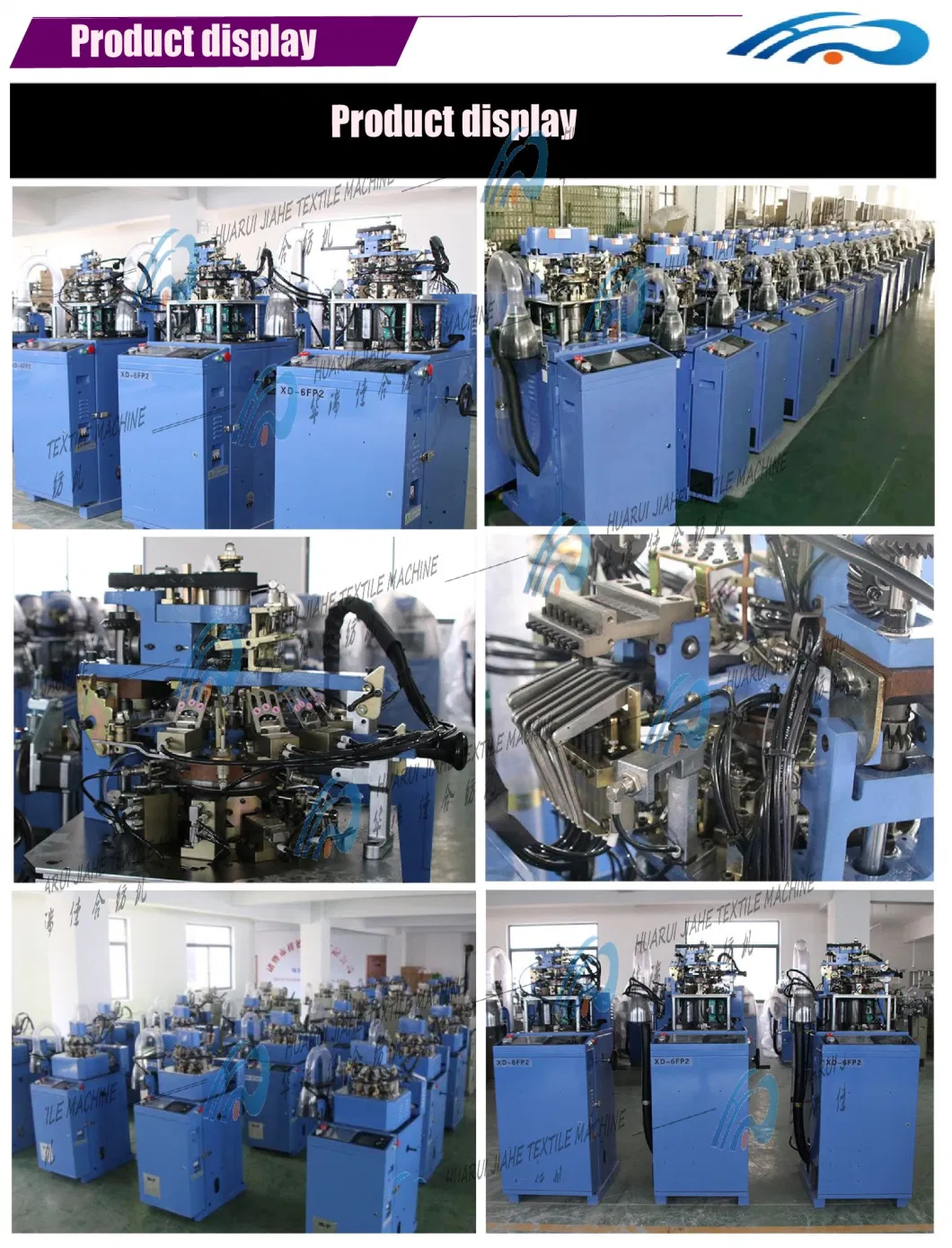

| Production Capacity | 100/Week |

Product Description

Brief introduction:

1, Application

This is 3.75 inch terry and plain socks making machine which is designed as a double-use socks machine. The machine can make both thin (summer) socks and thick (winter socks) and more popular in countries

2, Standard configuration

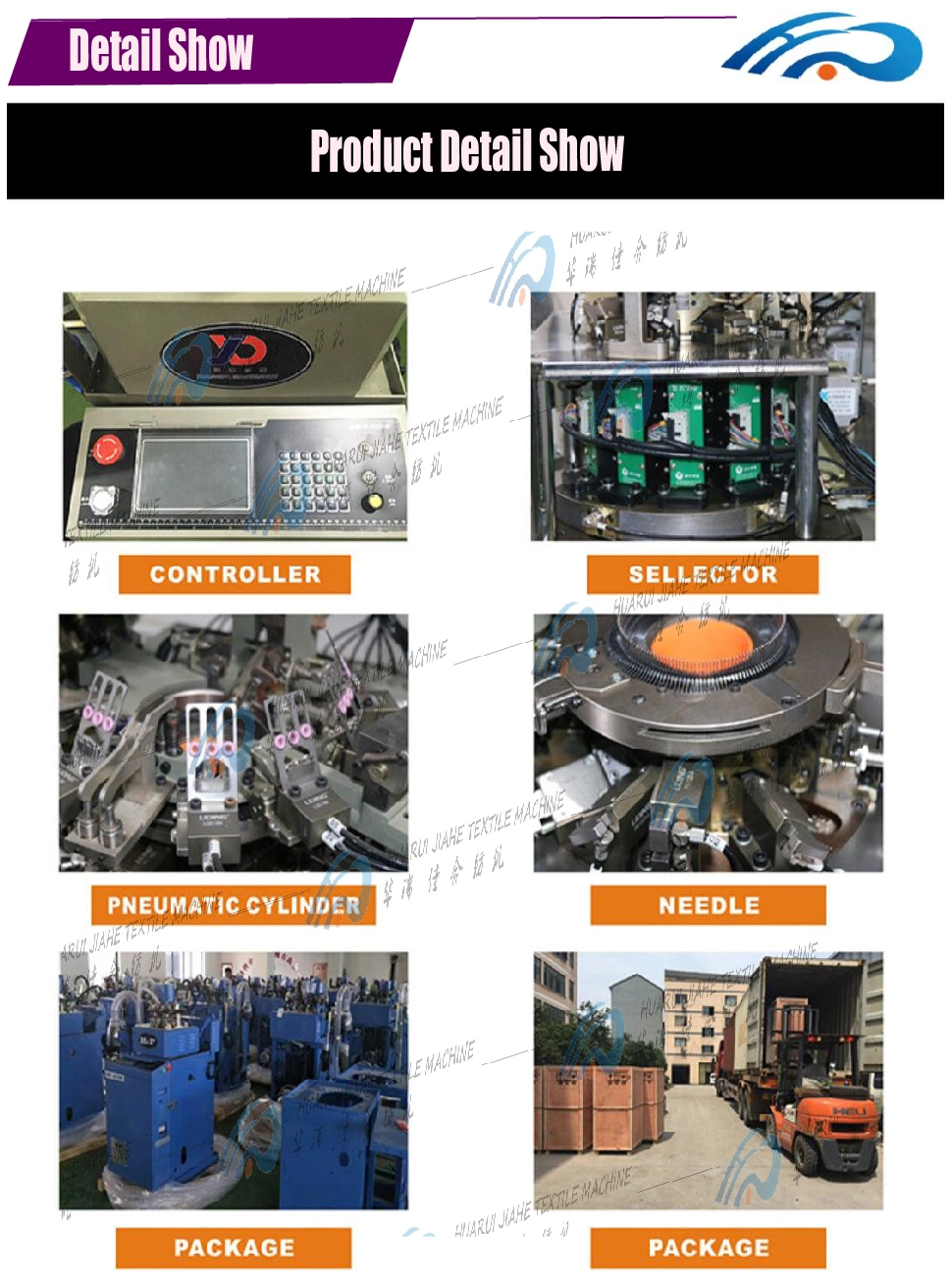

1. Controller: Mingde controller is adopted, which is compatible with glory system, Glory, Hengqiang(Jiagu Software) are also optional2. Servo Motor: Royaltec or Y.M.C, both of them are stable in performance and less repair rate3. Pneumatic Cylinder: LIDING, best brand in China4. Selector: Mingde brand as standard configuration, Fushun brand will be optional if buyer requires5. Needles: Feijian or Golden Roc brand.6. Cams: CR12MOV material are used instead of casting part, which has a longer life7. Standard air valve configuration8. Package: Plywood case, usually 18 sets can be loaded in a 20ft container and 39 sets in a 40ft container9. Electricity Required: 380V 3-phase

3, Optional Configuration

1. Suction fan motor 1.1kw (for small quantity of sock machine, below 10 sets, individual suction fan motor is suggested, if over 10 sets, central suction fan motor is better, which can help save electricity consumption greatly)2. Solenoid on main feeders, sub-feeders, valve box3. Double elastic motors, double elastic feeders 4. Invisible sock function 5. BTSR yarn break sensors6. LGL or Chinese brand accumulators7. Robert yarn creels8. Power: 220V 3-phase9. Machine colors: blue or grey

4, Needle counts.

5, Pre-production equipments

1. Air compressorIt is used to press the air to help sock machine change the working needles. 2. Air storage tankIt is used to storage the pressed air.3. Cooling drier & FilterThey are used to filter the water vapour, impurity, etc.4. StabilizerIt make the voltage stable, then reduce the damage of socks machine. 5. Suction fan motorIt is an equipment which is used to suck the finished socks up from socks machine. There are two kinds can be choosen: 1) Individual suction fan motor: if the quantity of socks machine is 1, 2, 3 or 4 sets, this motor will be suitable because it is installed inside of machine which can save the space; 2) Central suction fan motor: it is suitable for a large quantity of socks machine because one set motor can support 5sets, 10 sets, 20 sets even more socks machine working.

6, Parameters:

| 3.75 Inch Plain & Terry Socks Knitting Machine Technical Specification | |

| Cylinder Diameter | 3.75"(3.5''/4.5''/5'') |

| Needle Number | 72N-168N, 200N |

| Maximum Speed | 280~330 R.P.M |

| Driving Control | Servo Motor |

| Servo driving/motor Power | 0.85KW |

| Voltage | 380V/220V(optional) |

| Main Motor | 1.3KW |

| Fan | ≥1.1KW(Optional) |

| Control Box | 0.8KW |

| Site Area | 150*100*200cm |

| Net Weight | 250KG |

| Gross Weight | 305KG |

| Package Size | 90*75*160cm (1.08CBM) |

| Production Capcity | 250~350pairs(terry socks); 300~380 pairs/(plain socks)24 hours according to different sizes of socks |

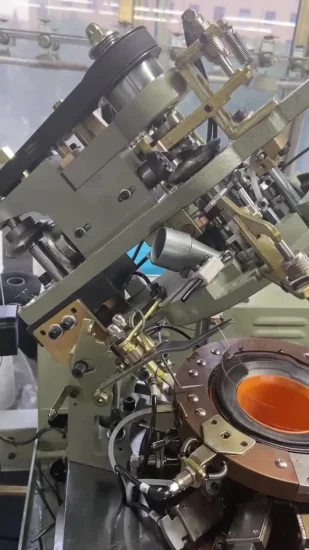

Detail machine pictures, all photoes are for 100% real shooting ! For more pictures, video and details, please email me!

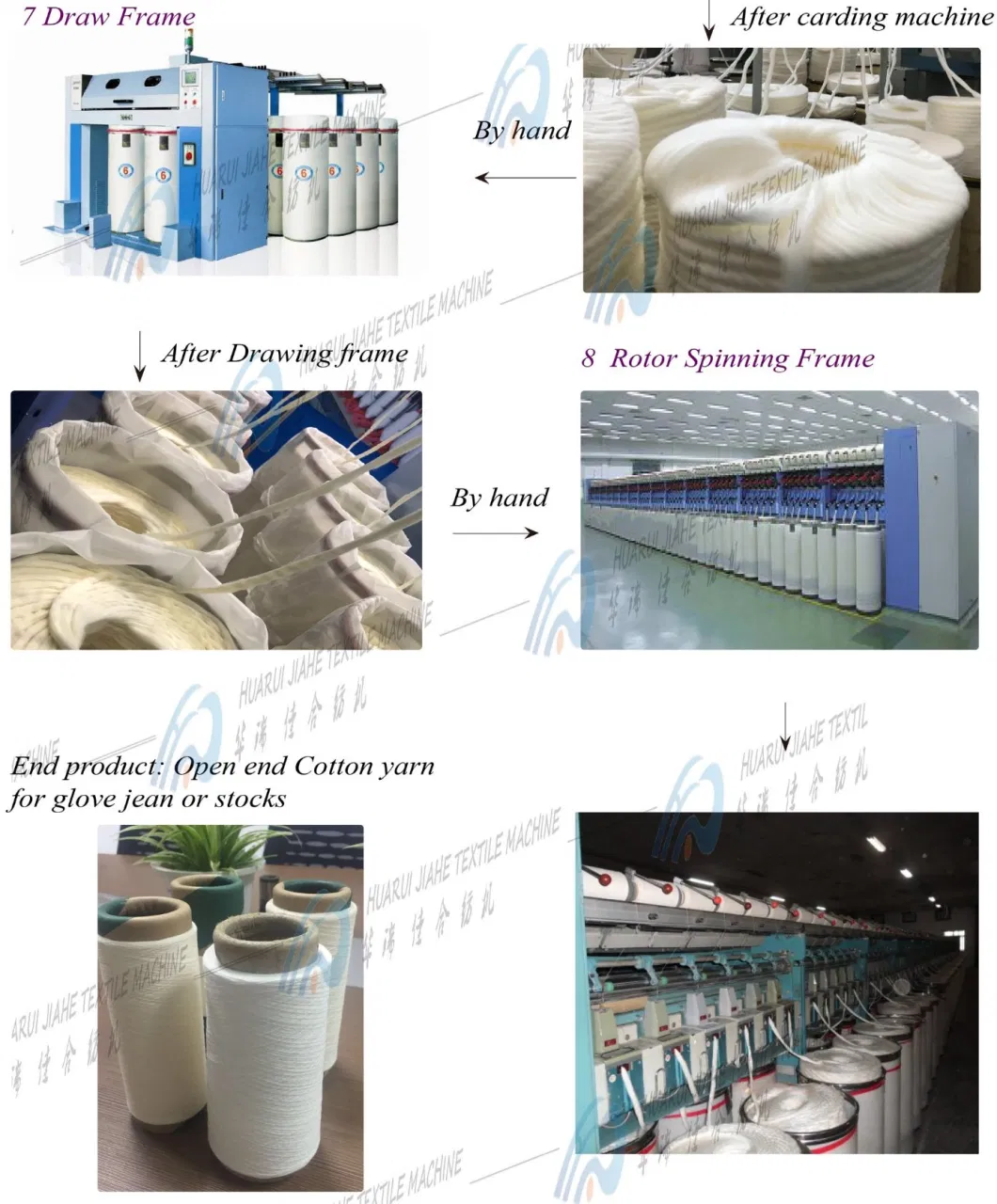

This machine can be used after open end yarn spinning line:

open end yarn raw material can be produced from recycling production line from waste colth, garment and other textile fabric.